WETRON Automação Ltda was founded in 1997 in Brazil in an effort to ensure the quality of WETRON’s projects throughout South America.

WETRON has three offices in Brazil. The main office is in São Bernardo do Campo – SP, with support from two offices in the cities of São Jose dos Pinhais-PR and Camaçari-BA. It has a staff of over 100 professionals who are capable of undertaking and supervising projects with a total of 250 employees. It offers its clients the highest quality projects and guarantees 100% compliance with its commitments.

In 2004, WETRON BRAZIL started working for the automotive industry through turnkey installations that integrated mechanical components built using technology exclusive to the company, and manufacturing and doing the mechanical and electrical installations for conveyors, cells and robotic welding, painting and surface treatment lines.

Most of the projects requested by our clients are turnkey projects.

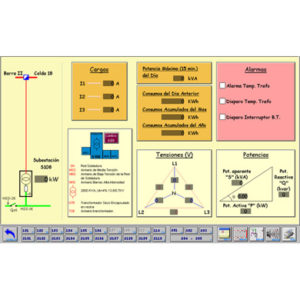

Most of the projects requested by our clients are turnkey projects. At WETRON automation technology, we study, plan and size the hardware and software for the projects we undertake.

At WETRON automation technology, we study, plan and size the hardware and software for the projects we undertake.

Our programmers, who have ample experience on several projects, develop software in the following areas:

Our programmers, who have ample experience on several projects, develop software in the following areas: In our shops we assemble 100% of the enclosures for our projects. This lets us reduce delivery times and ensure quality.

In our shops we assemble 100% of the enclosures for our projects. This lets us reduce delivery times and ensure quality.

The start-up of the installation is the last phase of a turnkey project. Our team of highly experienced professionals ensures a fast and trouble-free start up.

The start-up of the installation is the last phase of a turnkey project. Our team of highly experienced professionals ensures a fast and trouble-free start up. At WETRON, we vow to provide full support for all of the technology we implement. In keeping with this pledge, we offer training for operators and maintenance personnel at the client’s facilities.

At WETRON, we vow to provide full support for all of the technology we implement. In keeping with this pledge, we offer training for operators and maintenance personnel at the client’s facilities. WETRON has been a pioneer in developing electronic boxes with integrated PLCs for EMS trolleys since the 1970s. Ever since, it has led the way in developing, manufacturing and supplying products:

WETRON has been a pioneer in developing electronic boxes with integrated PLCs for EMS trolleys since the 1970s. Ever since, it has led the way in developing, manufacturing and supplying products:

We work in concert with leading system integrators for logistics centers and warehouses in the textile, food, pharmaceutical and other sectors, undertaking projects involving different technologies:

We work in concert with leading system integrators for logistics centers and warehouses in the textile, food, pharmaceutical and other sectors, undertaking projects involving different technologies:

We carry out projects to install and control various systems in factories:

We carry out projects to install and control various systems in factories: